Leica Geosystems surveys the world

Individual typeplates are marked by laser

Heerbrugg city in Swiss St. Gallen: Nature offers lush green vineyards and an impressive view of the Alps. Lake Constance is a half-an-hour drive.

Leica Geosystems, part of Hexagon, has been a major player on site for more than 100 years. Its instruments and software enable surveyors and other professionals capture, process and display geodata efficiently and accurately. Interiors, buildings and bridges, roads and industrial plants, pipelines, geoseismic changes and energy capacities in solar parks can be measured, positioned and visualized.

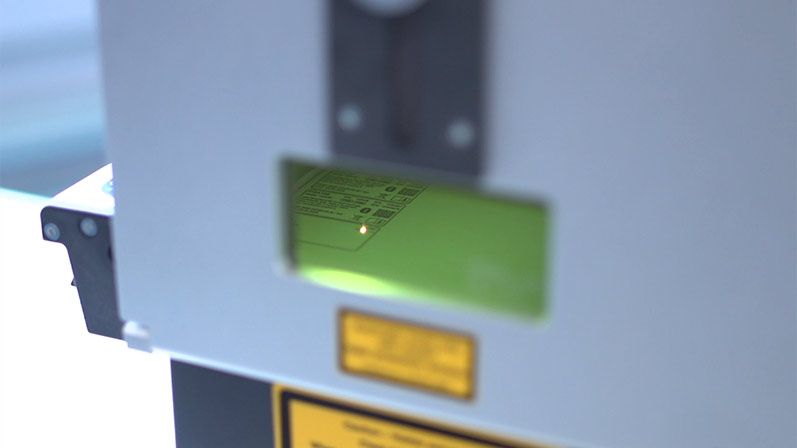

Information related to a product or a customer must be clearly legible on the instruments at all times and anywhere. Leica Geosystems indicates such typeplates individually specified to a customer using cab LM+ label marker systems and synthetic film labels marked by laser.

Upon recommendation

“Labeling is an important task in our processes. We are thus indicating about 80,000 instruments each year”, Patrick Frei says. He is Junior Project Manager and calls the easy handling of the equipment by Leica operators a basic requirement, as well as multiple interfaces: “The cab systems”, he adds, “meet such demands and provide even more”.

Leica Geosystems received a hint about cab three years ago from a local partner that, at that time, had already been working successfully with cab. Leica Geosystems and cab quickly found common ground. Today, two LM+ devices are in use in Heerbrugg. But that will not be the end of it. Gradually, all distribution centers worldwide are also going to be equipped with at least two Label Markers.

Permanently legible

Previously, labeling had been the job of thermal transfer printers from a cab competitor. The overall result was not satisfactory. Images on labels sometimes faded within few years. Mr. Frei points out to possible risks thereof: “Errors or accidents when operating a unit may occur if safety instructions are no longer clearly legible. We want to prevent from complications at any rate.” A new solution was sought elsewhere and found in cab.

- Outstanding functionality! cab Sales contact Mehmet Seker (pictured right) in talks with Patrick Frei about the benefits of the cab Label Marker.

Fiber laser

XENO 4 fiber lasers are particularly economical if top markings are required in conjunction with high performance and long life cycles of a marking system. The core of a glass fiber forms the laser-active medium. They match with the demands of Leica Geosystems, thus operate highly efficient. Focus on smallest spots is another benefit, even if they are hard to access, so are high processing speeds. No mechanical stress is exerted on the objects. Lasered data – part IDs, numbers of articles, series and customers, work orders – resist to UV radiation, heat and wear.

XENO 4 consists of a control unit with a beam source and a scan head linked to the beam source. To bundle the laser beam, the scan head features a planospherical lens. By this, specified marking fields can be covered. The laser system provides cablase software ex factory.

Film marker

XENO 4 marking lasers find use in a wide range of applications. As for a LM+ solution, cab supplies the laser system on a mobile cart, with an external rewinder on console, a monitor column and a filter system. It is possible to mark labels of different sizes from one roll of film. The laser removes the varnish layer. Markings are high-contrast and durable. The film labels can be separated by a cutter or rewound using an external rewinder.

- Labels marked by laser make GNSS antennas permanently verifiable and traceable.

Example of manufacturing

Leica offers a comprehensive product portfolio. Total stations on a stand for surveying construction should be familiar to everyone. Also on offer are tools for locating cables and wires, controlling machines, laser trackers and scanners, levels and software, for instance, to seamlessly connect measuring sensors for maximum productivity. GNSS satellite navigation in conjunction with Leica field solutions is, amongst others, efficient for positioning tasks with excavators on a construction site.

GNSS antennas are assembled, marked and tested in various steps at Leica Geosystems‘ manufacture facility Elements must be scanned and screwed, cables installed, shock absorbers bond and elements ultrasonically welded. Spots to apply labels on products are cleaned, labels are laser-marked by LM+ specified to customers and made available to operators. All they need to do is remove the labels from their liner with tweezers and stick them to the surfaces of antennas. Each element receives a final check, tested for leaks, before leaving manufacture.

200 years of tradition

“Digital images help to understand our world and make better decisions”, Mr. Frei says. The origins of Leica Geosystems date back more than 200 years, to the founding of Kern & Co. in 1819. Around 100 years later, the first entirely portable angle encoder was formed in Heerbrugg under the Heinrich Wild brand. It was the cornerstone of modern measurement. The company evolved into Leica Geosystems and is now part of the global Hexagon Group.

www.leica-geosystems.com

Video of this operation

Case study Leica Geosystems: Individual typeplates are marked by laser

January 2025