SQ 1000 applicator

vergrößern

vergrößern

| Applicator | SQ 1000 - 220 |

SQ 1000 - 300 |

SQ 1000 - 400 |

SQ 1000 - 520 |

|---|---|---|---|---|

| Operated with | SQUIX 2, SQUIX 4.3, SQUIX 4, SQUIX 4.3 M, SQUIX 4 M, SQUIX 6.3 | |||

| Cylinder strokemm | 220 | 300 | 400 | 520 |

| Stroke of a pad as calculated below a unitmm | 64 | 144 | 244 | 364 |

| Weight packaging excludedkg | 4.5 | 5 | 5.5 | 6.0 |

| Consumption of powerW max. | 15 | |||

| Compressed airbar | 4.5 | |||

| Cycle rateca.1) | 25 labels/min | |||

Automatic labeling

SQ 1000 is a further development of the proven S1000 applicator, fully compatible, adding extra functions. Existing applications can continue without limitations. In conjunction with a SQUIX printer, the SQ 1000 is a cost-effective solution for semi-automatic labeling tasks. Labels are applied onto items by means of a stroke cylinder.

Easy to configure

The applicator can be fully set on the printer control panel, configurations be stored and called up. Automatic calibration features speed up the setup.

Process control

Detailed statistical values are provided, so are sophisticated error messages. Constant control enables response right away in events of errors.

Updates

Applicator firmware can be updated on the printer control panel or the printer‘s web server. New features and specific solutions can therefore be tested right away and distributed in the field.

SQ 1000 applicator

1 Long life cycles: The ball bearing guide bars are low wear.

2 Different levels of application: By providing different lengths of stroke for the cylinder, labels can be applied on various heights to an item.

3 Compressed air regulation: Micro filters prevent from contamination. Decompression keeps the quality of label applications consistently high.

4 Reliable processes: Supporting air, intake air and stroke speeds can all be set. The pressing force can be reduced to less than 10N (1kg) in sensitive operations. Purging the intake ducts subsequent to every label application prevents from contamination.

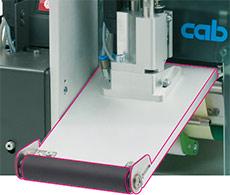

5 A wide range of sizes: Labels 25 mm to 176 mm wide and 25 mm to 200 mm high can be applied.

6 Supporting air: (Blow tube not included in delivery) It enables labels be blown onto a pad.

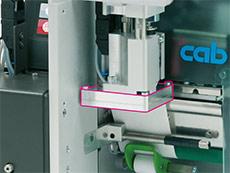

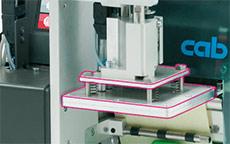

7 Pad: Labels are transferred onto a pad and held there by vacuum. A stroke cylinder moves the pad with the labels to an item.

Video: Label printer SQUIX with applicator S1000

A stroke cylinder applies the labels to products.

Note: The video shows the predecessor model S1000.

3D models for this applicator in STEP format you can find in documentation of SQUIX.

Documentation

-

Catalogs

-

Title Format Version Last change Language SQUIX

PDF - 6.88 MB 03/2025 27/03/2025 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions Applicator SQ 1000

PDF - 2.74 MB 11/2024 29/11/2024 English -

Other languages

-

Title Format Version Last change Language Notice d'assemblage Applicateur SQ1000

PDF - 1.42 MB 11/2024 29/11/2024 Français Montageanleitung Applikator SQ 1000

PDF - 2.75 MB 11/2024 03/03/2025 Deutsch

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual Applicator SQ 1000

PDF - 3.91 MB 11/2024 22/01/2025 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung Applikator SQ 1000

PDF - 3.91 MB 11/2024 22/01/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List SQ 1000

PDF - 788 KB 10/2024 22/01/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste SQ 1000

PDF - 792 KB 10/2024 15/10/2024 Deutsch

-

-

-

Assembly Instructions Spare Parts

-

Title Format Version Last change Language Montageanleitung Neubekleben Stempel / Assembly Instruction Re-gluing Stamp

PDF - 822 KB 08/2024 23/08/2024 English/Deutsch

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Firmware periphery

-

Title Format Version Last change Language Firmware applicators SQ, HQ

ZIP - 49 KB 2.1.0 08/04/2025 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader