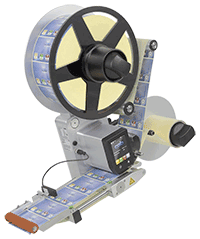

Labeling head

IXOR

Smallest servo-driven labeling head in its performance class

Smallest servo-driven labeling head in its performance class

A future-proof investment

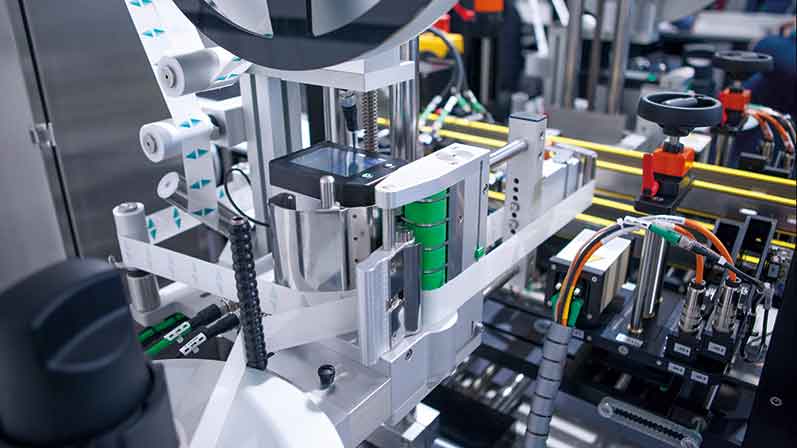

In the matter of mechanics, the IXOR can be ideally integrated in fully automatic labeling machines with the help of a modular construction kit. It can also be assembled to the conveyor belt of a production line by means of accessorial stands. Pre-printed labels are applied on products or packaging fast and precisely.

The device has the control unit integrated, a separate control cabinet is not required. The base unit can be selected from four structural widths in right-hand and left-hand designs. Unwinders pick up label rolls with 410 mm maximum outside diameter.

Zero downtime is possible through a redundant system.

The labeling head is a key component for smart production. The LAN and WLAN interfaces enable the device to be connected to the superior control units of machines.

MQTT, Modbus and OPC UA ensure cross-platform and future-proof communication. Protocols are kept simple and lean, machine and plant data can be submitted event-driven. If data values change, updates are possible in real time.

Remote IXOR operation with a smartphone, a tablet or a PC is possible at any time. The intuitive web interface allows backup, restore and updates.

Examples of construction

Construction L - left-hand

Assembly V - vertical

Pictured:

1.1 Labeling head 124 L

2.1 Unwinder D310 V 124 L

Outside diameter D: 310 mm

Construction R - right-hand

Assembly V - vertical

Pictured:

1.1 Labeling head 124 R

2.2 Unwinder D410 V 124 R

Outside diameter D: 410 mm

Construction R - right-hand

Assembly V - vertical

Pictured:

1.1 Labeling head 124 R

2.1 Unwinder D410 V 124 R motor-driven

Outside diameter D: 410 mm

Construction L - left-hand

Assembly H - horizontal

Pictured:

1.2 Labeling head 186 L

2.2 Unwinder D410H 186 L

Outside diameter D: 410 mm

For more examples of construction see delivery program starting on page 19.

to detect particularly thin or transparent label materials.

cab systems developed for printing and applying labels provide proper features by default, fairly protecting your data in a network.

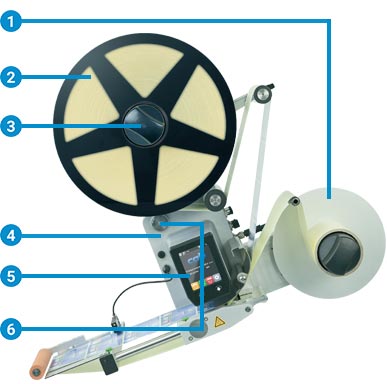

Details - standard labeling head

The subsequent illustration shows a very common IXOR version. This configuration is characterized by an economic and compact construction.

The unwinder and the rewinder are mounted directly on the base unit and operate without a separate drive. In contrast, the illustration below shows an IXOR with a motor-driven unwinder and a motor-driven rewinder, enabling to process large label rolls.

- Labeling head 124 L,

picking up label roll diameters up to 310 mm

1 Rewinder

When the labels have been peeled off, the liner tape is rewound. The swing lever and an integrated coupling enable the liner tape to be constantly tensed after passing the drive roller.

2 Unwinder

picking up label rolls with 310 mm (optionally 410 mm) maximum outside diameter. The swing lever and an integrated brake mechanism enable constant tension of the label web.

3 (Label roll) core retainer

By turning the handle, the core of the label roll is tightened and released again.

4 Base unit

made of cast aluminum. Basis to assemble all the units. The chassis possesses protection class IP66, NEMA 250 type 12. Further included is the drive unit consisting of a highly dynamic and high-torque servo motor.

5 Operation panel

Colored 3.5“ LCD touch display. In case of overhead assembly, the display can be rotated by 180°.

6 Pick-up points

on bars with 30 mm diameter. By moving the system, the position of the label on the product can be adjusted transverse to its transport direction.

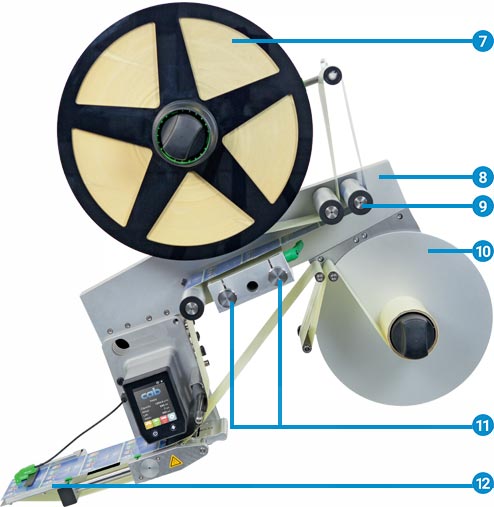

Details - labeling head with motor-driven winders

- Labeling head 124 L,

picking up label roll diameters up to 410 mm

7 Motor-driven unwinder

picking up label rolls with 410 mm (optionally 510 mm) maximum outside diameter. An integrated, brushless torque motor rotates the label roll and unwinds the label web according to the swing lever position.

8 Fixing bar

to pick up all the units: base unit and motor-driven winders

9 Deflection rollers

to guide the label web from the motor-driven unwinder to the base unit. Diameter 38 mm as pictured above

10 Motor-driven rewinder

When the labels have been peeled off, the liner tape is rewound. The swing lever and an integrated, brushless torque motor enable the liner tape to be constantly tensed after passing the drive roller.

11 Pick-up points

see position 6

12 Peel-off plate

to be application-specifically configured with the help of a comprehensive construction kit.

More specific informationen to operation panel, software features and base unit please see IXOR product catalog.

| Structural width | |||||

| Labeling head | 124 mm | 186 mm | 248 mm | 310 mm | |

|---|---|---|---|---|---|

| Performance | |||||

| Web speed up to m/min Web speed up to ipm |

25, 50, 100, 200 - depending from device model 1,000, 2,000, 4,000, 8,000 - depending from device model |

||||

| Material | |||||

| Labels on roll | Paper, plastics PET, PE, PP, PVC | ||||

| Thickness mm | 0.055 - 1 | ||||

| Weight g/m2 | 60 - 700 | ||||

| Width Labels1) up to mm | 120 | 182 | 244 | 306 | |

| Width Liner tape up to mm | 124 | 186 | 248 | 310 | |

| Label length mm | 5 - 6,000 | ||||

| Media roll Outside diameter | 310/410 mm (12"/16") | 410 mm (16") | |||

| Media roll Core diameter | 76 mm (3") | ||||

| Media roll Winding | outside or inside | ||||

| Weight up to kg | 15 | ||||

| Labeling head sizes and weights | |||||

| Height x Width with media roll 310 mm min. mm | 600 x 600 | - | |||

| Height x Width with media roll 410 mm min. mm | 700 x 680 | 825 x 925 | |||

| Depth mm | 266 | 328 | 390 | 452 | |

| Weight min. kg | 14 | 14.5 | 15 | 32 | |

| Device data | |||||

| Drive | AC servo motor | ||||

| Operation panel | QVGA-resoluted LCD color display | ||||

| Masterencoder (option) | 24 V HTL, track A + B | ||||

| Orientation of assembly | vertical / horizontal | ||||

| Label sensor | |||||

| Method | Transmitted light, inductive, capacitive2), ultrasonic2) | ||||

| Function | Detection of label margins and end of materials | ||||

| Interfaces | |||||

| Digital I/O interface | 17 pin, 24 V PNP to communicate signals with a superior control unit (galvanically isolated) | ||||

| Analog | Inputs (0-10 V / 0-24 V) for speed, START, STOP parameters in conjunction with PLC supplied by the customer or potentiometer (galvanically isolated) | ||||

| LAN | MQTT, Modbus, OPC UA, Ethernet/IP2) | ||||

| WLAN | WLAN 802.11 b/g/n, 150 MBit/s, 2.4 GHz | ||||

| Periphery (APPLY) | 12 pin, to connect USB warning light and applicator (24 V PNP, galvanically isolated) | ||||

| End of web sensor | 5 pin, 24 V PNP or end of web sensor by cab | ||||

| Start and stop sensor | 5 pin each, 24 V PNP (galvanically isolated) | ||||

| Synchronized product speed | 5 pin, 24 V PNP external synchronization signal or by masterencoder (galvanically isolated), masterencoder is an option | ||||

| Serial (option) | RS232/RS485 | ||||

| Operating data | |||||

| Mains I Protection class | primarily TN and TT grids I Protection class I | ||||

| Power supply I Power consumption | 100 - 240 VAC, 50 - 60 Hz I up to 4 A | ||||

| External fusing | 120 V: at least 6 A slow, up to 20 A / 230 V: at least 3 A slow, up to 16 A | ||||

| Leakage current | EN 60950: 260 V / 60 Hz: 1.0 mA | ||||

| Type of protection | IEC 60529: IP 66, UL 50 type 12, NEMA 250 type 12 | ||||

| Temperature / humidity Operation | 0 - 40 °C / 10 - 85 % not condensing | ||||

| Temperature / humidity Stock | 0 - 60 °C / 20 - 80 % not condensing | ||||

| Temperature / humidity Transport | –25 - 60 °C / 20 - 80 % not condensing | ||||

| Approvals | CE, FCC, IC, ICES-3, CB, cULus | ||||

| Operation panel | |||||

| LED buttons | ON, FEED | ||||

| LCD graphics display Width x Height mm | 54 x 70 | ||||

| Settings | Language settings, device settings, interfaces, memory for 100 product formats | ||||

| On display | Operational and warning messages | ||||

| Monitoring / test routines | |||||

| Label web | Pre-warning to end of label web, end of label web, label web broken | ||||

| Drive | Torque, temperature, power supplies, currents | ||||

| Electrical outputs | Overload protection, short circuit, reverse polarity | ||||

| System | Diagnostics when device is switched on, I/O test menu integrated | ||||

- The label size is further defined by the type of applicator. Limitations may apply to small labels, thin materials or strong adhesive. Such applications need to be tested.

- on request

For more technical data see our product catalog (PDF)

| Structural width | |||||

| Winder motor-driven | 124 mm | 186 mm | 248 mm | 310 mm | |

|---|---|---|---|---|---|

| Performance | |||||

| Web speed up to m/min Web speed up to ipm |

125 5,000 |

||||

| Material | |||||

| Labels on roll | Paper, plastics PET, PE, PP, PVC | ||||

| Thickness mm | 0.055 - 1 | ||||

| Weight g/m2 | 60 - 700 | ||||

| Width Labels up to mm | 120 | 182 | 244 | 306 | |

| Width Liner tape up to mm | 124 | 186 | 248 | 310 | |

| Label length mm | 5 - 6,000 | ||||

| Media roll Outside diameter | 410 / 510 mm (16" / 20") | ||||

| Media roll Core diameter | 76 mm (3") | ||||

| Media roll Winding | outside or inside | ||||

| Weight Unwinder up to kg | 30 | ||||

| Weight Rewinder up to kg | 15 | ||||

| Winder sizes and weights | |||||

| Height x Width with media roll 410 mm min. mm | 430 x 490 | ||||

| Height x Width with media roll 510 mm min. mm | 530 x 590 | ||||

| Depth mm | 266 | 328 | 390 | 452 | |

| Weight min. kg | 7 | ||||

| Device data | |||||

| Drive | brushless torque motor | ||||

| Orientation of assembly | vertical / horizontal | ||||

| Interface | |||||

| Digital I/O interface (option) | 12 pin, 24 V PNP to communicate signals with a superior control unit (galvanically isolated) | ||||

| Operating data | |||||

| Mains I Protection class | primarily TN and TT grids I Protection class I | ||||

| Power supply I Power consumption | 100 - 240 V~, 50 - 60 Hz I up to 2 A | ||||

| POWER IN I POWER OUT | up to 12 A I up to 10 A | ||||

| External fusing | 100 V: at least 3 A slow, up to 20 A / 230 V: at least 1.5 A slow, up to 16 A | ||||

| Leakage current | EN 60950: 260 V / 60 Hz: 0.5 mA | ||||

| Type of protection | IEC 60529: IP 66, UL 50 type 12, NEMA 250 type 12 | ||||

| Temperature / humidity Operation | 0 - 40 °C / 10 - 85 % not condensing | ||||

| Temperature / humidity Stock | 0 - 60 °C / 20 - 80 % not condensing | ||||

| Temperature / humidity Transport | –25 - 60 °C / 20 - 80 % not condensing | ||||

| Approvals | CE, ICES 3, CB, c UL us, FCC Class A, IC | ||||

| Monitoring / test routines | |||||

| Label web | Pre-warning to end of label web, end of label web, label web broken | ||||

| Drive | Torque, temperature, power supplies, currents | ||||

| Electrical outputs | Overload protection, short circuit, reverse polarity | ||||

| System | Diagnostics when device is switched on | ||||

Ready to interact with machines and components of different manufacturers in industrial plants.

Which accessories fit to which model you can see in overview all accessories IXOR product catalog.

Documentation

-

Catalogs

-

Title Format Version Last change Language Labeling head IXOR

PDF - 4.32 MB 07/2021 11/04/2023 English Overview Product Marking

PDF - 6.61 MB 03/2025 13/03/2025 English

-

-

Programming

-

Title Format Version Last change Language Brief introduction to cab printer programming

PDF - 7.47 MB 04/2022 15/01/2025 English cabPROTECT - Data security in label printing

PDF - 472 KB 06/2024 20/06/2024 English -

Other languages

-

Title Format Version Last change Language cabPROTECT - Datensicherheit beim Etikettendruck

PDF - 475 KB 06/2024 20/06/2024 Deutsch Kurze Einführung in die cab Druckerprogrammierung

PDF - 7.50 MB 04/2022 12/04/2022 Deutsch Marquage en réseau avec OPC UA

cab et l'usine intelligentePDF - 745 KB 01/2022 23/10/2024 Français

-

-

-

Case study

-

Title Format Version Last change Language cab labeling heads, operated by Ankerkraut and GERNEP

Spices known from Die Höhle der Löwen, labeled in a professional wayPDF - 928 KB 06/2022 22/01/2025 English Covid-19 rapid test: A combination of machines providing, labeling and packing

PDF - 771 KB 08/2020 25/08/2022 English When precision is the target: Feeding, labeling and packing PCR tests

PDF - 859 KB 11/2021 25/08/2022 English

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Well-trained cab service engineers worldwide support in the maintenance and repair of the devices.

Software & Drivers

-

Firmware

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware IXOR

GZ - 58.73 MB 1.436 18/04/2024 – Release Notes Firmware IXOR

TXT - 34 KB

TXT - 34 KB

1.09 - 1.436 18/04/2024 –

-

-

Firmware periphery

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Ready to interact with machines and components of different manufacturers in industrial plants.

![[A] Pivoted device retainer [A] Pivoted device retainer](/media/images/_zubehoer/zubehoer193.jpg)